CLAY PRE-PROCESSING AND EXTRUSION PLANTS

CISMAC, through its highly qualified staff, is able to support and support the buyer in order to identify, with inspections, withdrawals and surveys, the quarry that offers the best performance; then provide, through meticulous instrumental tests in the laboratory, the chemical, mineralogical analysis and the various cooking samples, for a clear and tangible example of the possible results. The choice of the equipment necessary for the pre-processing of the clay is a consequence of the good work done before and in accordance with the principles of high quality, efficiency and productivity that distinguish the choices of CISMAC.

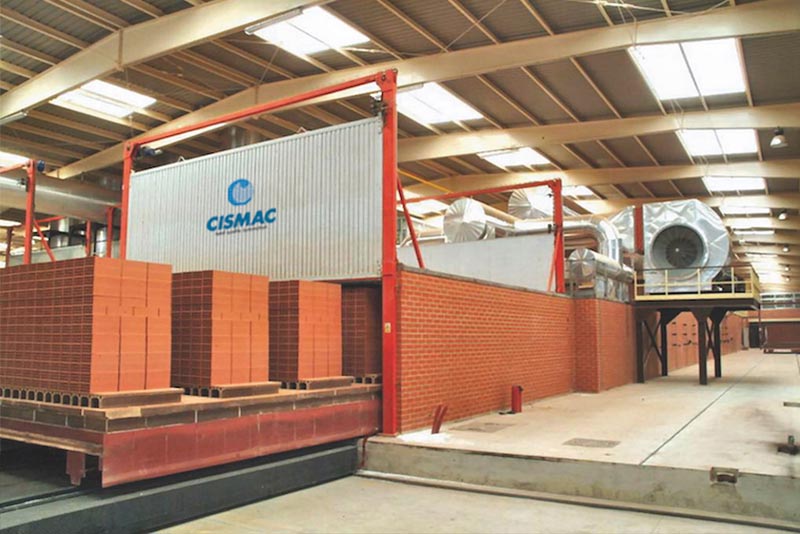

DRYING AND FIRING

CISMAC, thanks to its decades of experience in the field, to the development and scientific research activity and to the collaboration with universities, allows its technicians to propose innovative and technological solutions in the field of thermodynamics, fuidodynamics and ventilation. Drying and cooking are therefore the right combination of high technology, development and tradition. The dryers produced can therefore be static racks, semi-continuous or bilancelle. As for cooking, the kiln is made according to the traditional tunnel scheme, with "face to face" coating, then equipped with the most modern and advanced combustion equipment and a process to guarantee low consumption, high performance and certainty of results. Characterizations and sizing are specific to each project. An integrated and centralized system of plant supervision guarantees the optimization and overall control of the process.

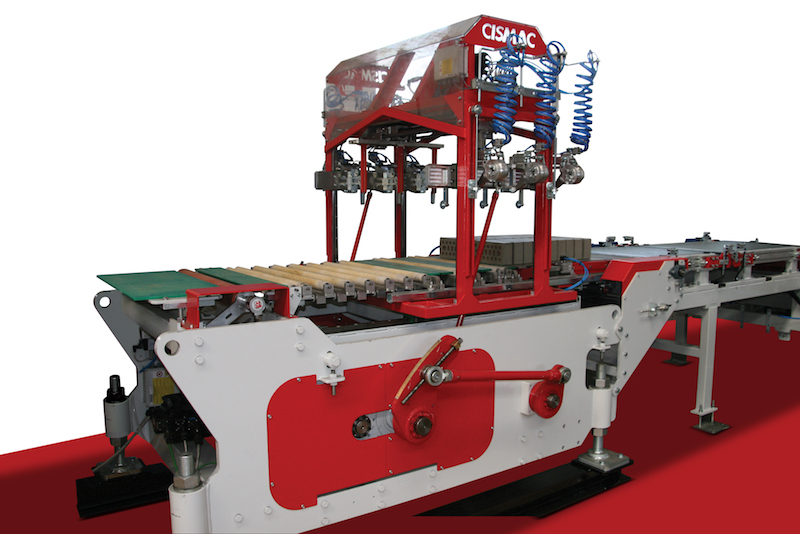

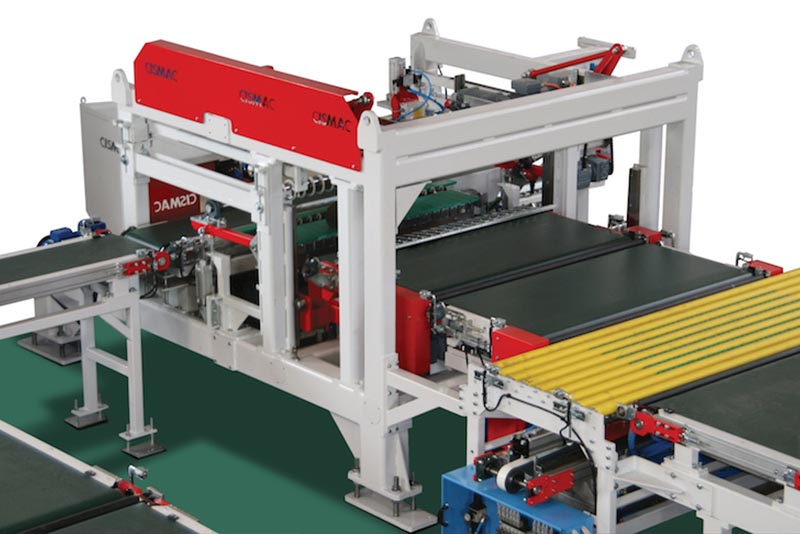

AUTOMATION, PACKAGING AND STORAGE

CISMAC, through the development and study of the different plant and production specificities required, designs and manufactures highly technological, performing and reliable solutions that see the use of traditional Cartesian or robotic equipment. An accurate design in addition to the use of advanced tools such as 3D CAD and off-line simulation, allows CISMAC to provide highly qualitative, high-performance solutions in line with the most modern production standards. Compliant and scrupulous in applying the TPM standards on assistance and maintenance, it guarantees a product that allows the achievement of high efficiency.

THIRD SPECIAL PROCESSES

A high level of specialization and a know-how gained over years of research and applications, are a source of pride and an index of strength for CISMAC. It is with these assumptions that our company has been creating highly customized solutions for years, aimed at transforming and customizing the final product that can allow our customers to stand out on the market. These are therefore plants and solutions to integrate the complete factory, which once again represent the propensity and partnership that is created between CISMAC and its customers, the will and desire that both have to want to create something exclusive and unique in its kind. Our ideas come to fruition!

DIGITAL PRINTING AND TREATMENTS

Cismac, thanks to its propensity for research, as well as its continuous presence on the market, has been able to develop and implement production processes and processes, which go beyond the production of the same but, now, propose to modify its aesthetic appearance and mechanical characteristics. In fact, thanks to the new lines of digital printing and surface treatment of the product, it is possible to obtain new products, aesthetically made according to personal taste or specific market needs, able to resist atmospheric agents, which allow their use in new situations and applications, never undertaken before.